|

The cost of downtime in manufacturing can range widely—from $1,000 to $15,000 per hour—depending on the size and scope of your operations. These costs accumulate quickly, straining your finances, disrupting workflows, and damaging employee morale. But the impact doesn’t stop there. Unplanned downtime can also delay projects, reduce customer satisfaction, and tarnish your reputation. The key to minimizing downtime lies in proactive maintenance, efficient business processes, and continuous monitoring. With the right tools—like a robust ERP system such as Fourth Shift—you can maximize uptime and profitability. |

|

Common Causes of Downtime Include

|

Direct Costs of Manufacturing Downtime: |

|

|

|

|

Indirect Costs of Manufacturing Downtime: |

|

|

|

|

|

How Innovative Consulting Group Can HelpAt Innovative Consulting Group, we focus on enhancing manufacturing operations and reducing downtime through customized strategies. Here’s how we can assist you: |

|

Do you have Process Gaps? Conduct a Comprehensive Business Systems ReviewA Business Systems Review includes a comprehensive analysis of your existing business processes, applications, and automation. Our expert team conducts detailed assessments to unveil gaps in your processes, procedures, and ERP maintenance. By closely examining your Fourth Shift ERP system, business workflows, and machine performance, we identify gaps that could contribute to downtime. Through a series of in-depth assessments, we uncover inefficiencies and create a targeted improvement plan that enhances operational reliability. |

|

Employee Training and EngagementA skilled, knowledgeable team is crucial for preventing downtime. That’s why we offer tailored training programs to ensure your employees understand the full capabilities of your ERP system. By investing in hands-on workshops focused on best practices in maintenance, troubleshooting, and process optimization, we equip your team with the tools they need to be proactive in preventing issues before they arise. This not only reduces downtime but fosters a culture of continuous improvement across your organization. |

|

Consider Platform Hosting SolutionsCloud-hosted ERP solutions like ICG's CloudFour offer round-the-clock support to ensure your ERP system functions smoothly without interruptions. By managing your Fourth Shift ERP on a secure cloud platform, we take the burden of system maintenance and monitoring off your team’s shoulders. Continuous support means your operations stay on track, and your IT team can focus on more strategic tasks rather than troubleshooting. |

|

Ongoing Support and EvaluationWe don’t just implement solutions and walk away. At ICG, we provide ongoing monitoring and regular performance evaluations of your Fourth Shift ERP system through our ERP Managed Services. Our team works proactively to optimize your system, reduce risks, and maintain peak performance. With us as your trusted partner, you can rest assured that your operations are always running at their best, with minimal downtime and maximum efficiency. |

Understanding the actual costs and causes of downtime is the first step toward mitigating it. At Innovative Consulting Group, we help you identify vulnerabilities in your operations, streamline your processes, and ensure that your Fourth Shift ERP system is optimized to keep things running smoothly. Our goal is simple: converting your downtime into uptime and boosting efficiency and profitability.

Reach out to us today to discover how we can help reduce downtime in your manufacturing operations and guide you on the path to operational excellence. Let’s work together to keep your systems—and your business—running at full capacity.

Minimize your downtime and contact ICG today.

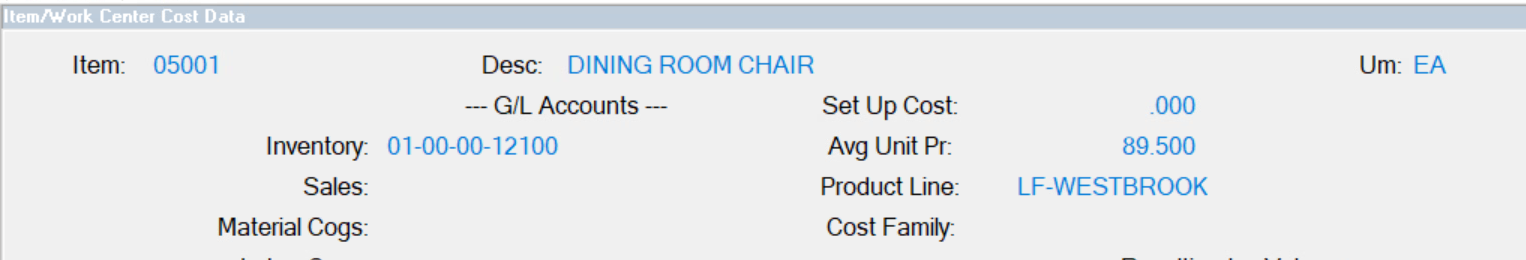

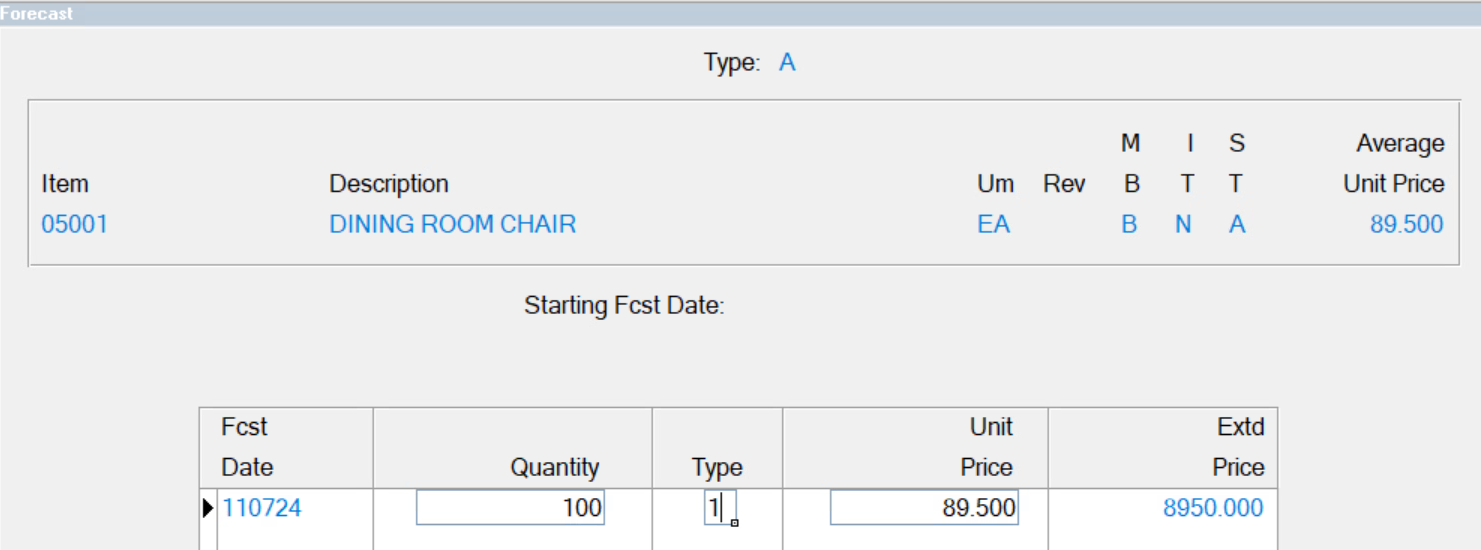

Fourth Shift ERP Quick Tip: When entering item forecasts, putting an item's average price in the Avg Unit Pr field in the header of the Item Cost Screen (ITMC) will cause the price to be placed on the Forecast (FCST) screen automatically.