Streamline Warehouse and Shop Floor Automation with MFGStream.

| Say goodbye to manual data entry, slowdowns in order fulfillment, and outdated inventory management. MFGStream automates repetitive tasks, reduces decision points, and helps you make more informed, faster business decisions. |

Why MFGStream is the Future of ERP-Agnostic Manufacturing AutomationMFGStream is a fully integrated, powerful ERP-agnostic platform that allows complete customization and automation of your manufacturing or distribution facility. MFGStream combines workflow, process, and transaction automation with a fast, user-friendly mobile interface. Quickly deploy workflow and barcode data collection functions instantly within your facility. Implement customized business processes and automation to detect and trigger events that respond in an automated fashion without user intervention. Developed by ICG and Shop Floor automation pioneer Keith Vincent, MFGStream performs hundreds of transactions with one scan. |

|

Key Features & Benefits:

|

✓ Automate Recurring and Repetitive Processes |

✓ Transactions Follow Business Processes (not limited by ERP) |

|

✓ Preserve Your Investment if You Move to Another ERP |

✓ Increase Productivity and Provide Full Visibility for Your Operation |

|

✓ Reduce Decision Points and Data Collection with Easy-to-Use UI on Mobile Devices |

✓ Design and Print all Labels Without Additional Licensing |

|

✓ Modern Development Platform |

✓ Improved Supply Chain Visibility |

About MFGStream Automation

|

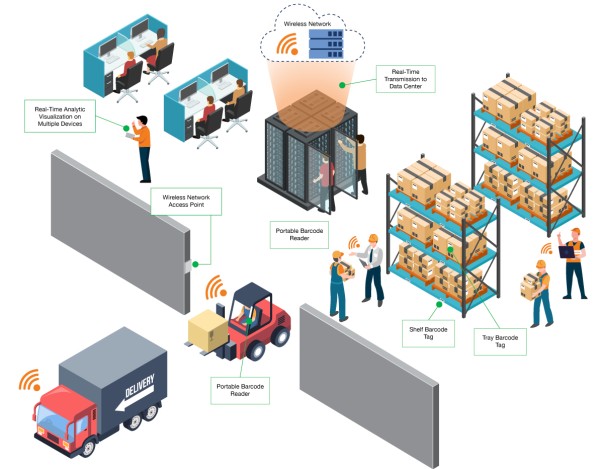

Warehouse Automation is the process of automating inventory movement into, within, and out of a warehouse with minimal human interaction. Any efficient warehouse can experience a delay in delivery times, which negatively impacts the customer experience and incurs unnecessary overhead costs. Contrary to widespread belief, Warehouse Automation only sometimes means physical or robotic automation; it often simply refers to using software to replace manual tasks. Deploying an automation strategy, such as MFGStream, does require some upfront costs. However, these costs usually pay for themselves through greater efficiency, increased sales, and improved customer service. MFGStream aims to reduce repetitive physical work, manual data entry, and analysis that can cause slowdowns in order fulfillment and inventory control. Interested in optimizing your ERP system? Check out our ERP Managed Services page for a complete solution. |

|

|

Rethink Workflow

|

Go beyond the built in and very limited ERP Shopfloor tools. Mid-tier ERPs lack scriptable shop floor process automation, data collection, and workflows.

|

|

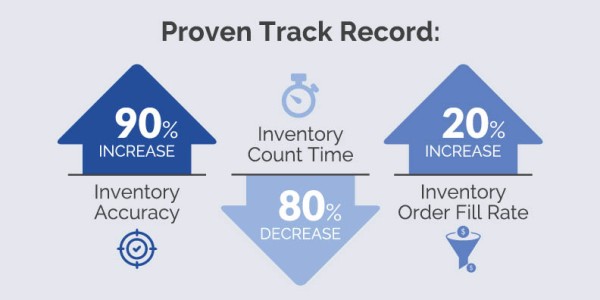

ICG's Manufacturing and Warehouse performance history over the last decade says it all. |

MFGStream is ERP-Agnostic

|

MFGStream is currently available for Fourth Shift ERP and VISUAL ERP. If your ERP is not listed, call our sales team and find out how MFGStream could work with your specific product. |

|

|

Contact Us to request a free MFGStream Demo or download the ICG MFGStream Product Sheet to learn more.