Earlier this week in our Banking VDI/DaaS Success Story post, we discussed how ICG helped a prominent local bank address its IT issues to gain better efficiency and increase customer satisfaction. Today, we'll discuss how we support ERP clients as well as IT ones. Fourth Shift ERP can sometimes be a difficult platform to customize, but it doesn't have to be! This customer scenario demonstrates how a single process change can help your business flourish with minimal cost and interruptions to your production.

The Problem |

|

|

A manufacturing facility reached out to ICG after struggling with significant challenges in its inventory management, resulting in production delays, inventory inaccuracy, and a negative impact on on-time customer shipments. Issues with locating items needed for production resulted in manufacturing delays, which affected production schedules, and impacted overall efficiency. The root cause of the problem was stockkeepers moving inventory to create part kits for orders without updating their ERP which was leading to inventory accuracy problems. As a result, parts went missing, inaccurate inventory was causing shortages for other production orders, and there was no visibility in the kits of parts being created. Addressing this inventory management issue promptly was imperative to restore inventory accuracy and visibility, which is why they called ICG to help. |

The Solution |

|

|

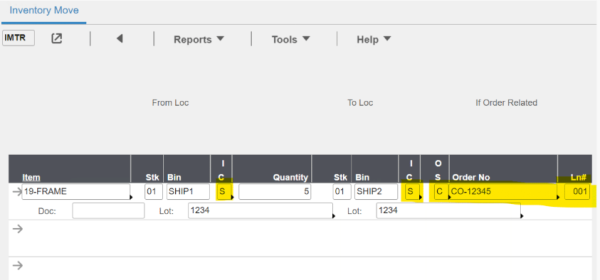

To address the inventory management challenges faced by the client, ICG began by implementing a Production Order Kitting Process. This process works as follows: |

|

A temporary stock location is created to hold the kits being built, which references the manufacturing order (MO) number. |

A label is produced that contains the Kit ID, the production order number, and the parent being produced, which is then affixed to the kit. |

Users are then directed on a guided walk-through inventory to select each required item for the MO from the available stock. |

|

|

An inventory move is generated for each item to take it from standard inventory and place it in the Kit location. |

Once the Kit is completely picked, a single delivery transaction is performed to move all kitted inventory from the Kit stock location to the work-center where the items are consumed by manufacturing. |

Finally, the temporary Kit stock location is removed from the ERP. |

|

|

This solution not only improved inventory accuracy and reduced production delays but also enhanced overall operational efficiency for the business. All this was done inside of MFGStream, an ERP agnostic platform that allows quick deployment of workflow and data collection functions. |

||

The Outcome |

|

|

With streamlined processes and accurate inventory tracking now implemented, the client witnessed smoother production operations. This has led to increased accuracy of inventory, quicker creation of order kits to support production, a reduction in item shortages in manufacturing, and visibility of all inventory within the facility. These improvements ultimately drove success and profitability for the business. ICG is dedicated to empowering manufacturing organizations to reach their fullest potential. With a proven track record spanning over a decade in improving manufacturing performance, we are the right team to help your organization excel.

|

For help with any ERP challenges, contact us.

Fourth Shift Quick Tip: Since version 8.0, stock can now be moved between staging locations! To use this function, you must enable in COCF and all quantity for the line must be moved to the same location.