Is Your ERP Really the Issue?

Since 1980, ERPs have been the backbone of manufacturing plants across the globe. Billions of dollars have been invested into implementations and upgrades with promises of enhanced process automation. But are manufacturing leaders saying it was worth it? According to Computer Economics, ERP systems have scored last regarding company satisfaction over the last few years. This is a concerning statistic when we think about how critical an ERP system is to the livelihood of a business. This raises an important question: Is it the ERP, or is there something more to it?

Love-Hate Relationship: |

Despite the dissatisfaction manufacturing decision-makers seem to have regarding their ERP system, they are still buying ERP systems or upgrading the ones they already have. What choice do they have: go back to spreadsheets and other manual systems? Manufacturing decision-makers recognize that ERPs benefit their business, but they approach the subject from a technology-only perspective. At ICG, our experience shows that it's more about embracing change and utilizing technology to drive advancement and efficiency. |

Evaluate Your Existing Software: |

A self-evaluation of your existing software is critical for maximizing your ERP's potential. Many companies experiencing dissatisfaction with their ERP underutilize their current software; end users often use less than 15% of their ERP software's capabilities. Underutilization is the #1 reason customers replace their ERP, and familiarizing your team with your ERP's full capabilities will enhance your satisfaction with your current ERP system. |

Trust Your Personnel: |

The most significant issue ICG finds is that manufacturing organizations don’t focus on their business processes and procedures or their end-users, which leads to them blaming software instead. They go through the process of selecting or upgrading their system, thinking it will solve all their issues. Still, they forget to consider how their users interact with the ERP. Decision-makers should consider the pain points, how end-users will be trained, and what systems and processes they want to automate or improve before investing their time and money. When these issues are not addressed first, you end up with frustrated end-users and more errors, which make your ERP look inefficient. |

Evolving Your ERP: |

When utilized to their full potential, ERPs help with your business's efficiency, output, and overall capability. Implementing the proper processes and procedures, running system updates, and adding any necessary ERP extension products will increase satisfaction and prolong the life of your current ERP software. The ever-changing health of an ERP requires staying up to date because they are constantly evolving. |

Your ERP is the primary vehicle driving your business, and its success coincides with the success of your business. While we see that Manufacturing Leadership, end-users, and C-levels tend to be unhappy when their ERP isn’t performing correctly, we know this doesn’t have to continue to be the issue. Next week, we will discuss steps to take and how ICG can help to ensure satisfaction with your ERP system.

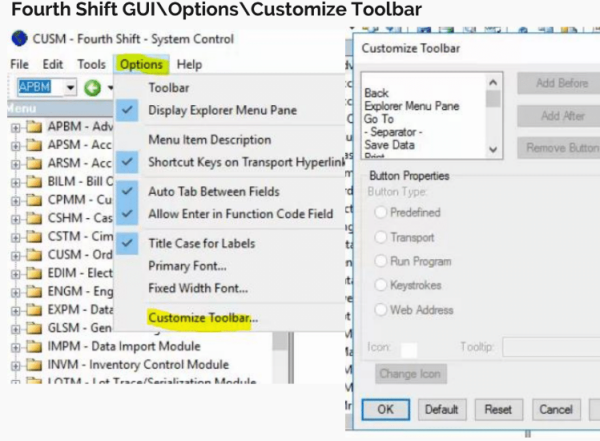

ERP Tidbit: Add shortcuts on the Fourth Shift Toolbar. On the Toolbar, follow this menu path: