In the world of manufacturing, your ERP is crucial in driving efficiency, productivity, and competitive advantage. However, what happens when neglect and lack of maintenance bring a critical system to its knees? This was the predicament faced by a manufacturing company that had allowed their VISUAL ERP to languish over two decades without relevant upgrades or proper maintenance. The company found itself desperately seeking a solution to resurrect its vital ERP system operations. ICG, armed with expertise and the top VISUAL resource in the country capable of fixing their ERP, intervened to assess the damage and devise a strategy to revitalize the ailing system.

|

The Problem |

|

A manufacturing company faced a critical dilemma stemming from neglecting maintenance on their VISUAL ERP over the span of twenty years. With no upgrades or database maintenance conducted during this time, the software had deteriorated to the point where it was no longer operational. The lack of ongoing care and updates had rendered their environment obsolete. Combined with the absence of individuals skilled in maintaining this system, the company found itself unable to revive or salvage their software, leaving them in a precarious position without a functioning solution for their needs. The customer diligently reached out to multiple providers, receiving no response, before they discovered ICG. Their diligence paid off as ICG quickly came to their aid and had the right expert capable of fixing their VISUAL ERP. We knew exactly what to do. Systems that aren't kept up-to-date are susceptible to vulnerabilities, hindering productivity and exposing organizations to potential risks such as data breaches and operational disruptions. Performance issues are exasperated with outdated systems leading to downtime and inefficiency. ERP systems that do not stay current face challenges in meeting regulatory requirements, resulting in penalties and loss of trust from customers. This manufacturing company learned this the hard way, but it wasn't too late. |

|

The Solution |

|

|

ICG’s decades of experience proved invaluable in tackling the challenge of reviving their down system. Our comprehensive knowledge and adept problem-solving skills enabled us to tailor a solution that precisely met the customers' needs. ICG's database team went straight to work and restored the system to operating performance. By reviving their old system, ICG not only averted risks of data breaches and operational disruptions but also empowered the client with a robust ERP system once again capable of driving growth and innovation. This highlights the critical importance of regularly updating and maintaining IT and ERP systems to safeguard against obsolescence and maximize operational efficiency. ICG's proficiency in both IT and ERP saved this company valuable time and money in creating a solution that addressed ALL of its internal issues. |

|

The Outcome |

|

Through innovative thinking and meticulous planning, we breathed new life into their down system. The company learned the vital importance of keeping ERP and technology systems up-to-date for business operations. These efforts paid off as the once-crippled software regained functionality. The client now experiences operational continuity, with productivity and efficiency levels back on track. With the software performing optimally, satisfaction among users and customers soared. Overall, the solution not only resolved the immediate crisis but also provided lasting benefits positioning the client for continued success. When safeguarding the heart of your operations – your VISUAL ERP – ICG is prepared with the expertise and dedication needed to keep your business at its best. Contact ICG today to ensure your IT and ERP systems remain secure, compliant, feature-rich, and efficient with knowledge and managed services. |

For help with any and all IT and ERP challenges, contact us.

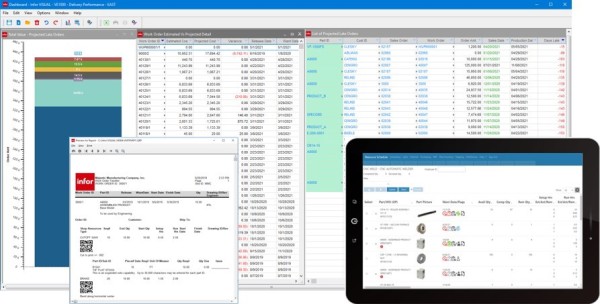

VISUAL Quick Tip: VISUAL offers a full range of dashboards and visuals to help identify production issues and execute on the shop floor. Manage material requirements by the job, by stocking levels, or a combination of both.