|

Looking for the ultimate guide to maximize your ERP's potential? Wanting to automate your shop floor and workflows throughout your entire operation? Effectively utilizing and implementing ERP can transform operations by boosting efficiency, reducing costs, and adapting to changing market demands. However, many companies struggle with where to begin. VISUAL ERP can automate your shop floor and workflow operations and, combined with ICG's proven approach, guarantee success. Here are six essential steps to streamline and improve your implementation or reimplementation strategy with VISUAL ERP. |

|

|

Education: Investing in Trusted ResourcesWe at ICG hear all the time, “We don’t know what our ERP can do”, “We’ve lost expertise”, or “I didn’t know that those tools or software extensions existed!”. Approaching implementation and automation from an experienced perspective makes all the difference. Augmenting your staff during ERP implementation with consultants or integrators ensures your staff is properly educated and you know exactly what you can get out of your ERP. It’s critical to work with a trusted resource like ICG to educate and inform you on what is possible with your ERP and the tools necessary to deliver the expected result. We believe it is important to first educate your team on the ERP system before we start investigating your current processes. Stick to the 80-20 rule for your ERP implementation: focus on getting 80% of the essential tasks done well rather than aiming for perfection. It’s more important to complete the major components and then address the remaining 20% with fixes and updates as you continue the process. Trying to achieve 100% perfection immediately is impractical because you can't anticipate every need of your organization. By prioritizing the key steps, you'll make steady progress and keep everyone happier in the long run. |

|

|

Discovery and Planning: Understanding Your ERP ProcessesTo effectively leverage your VISUAL ERP system, you must identify and document all the processes it supports and observe how they operate in real-world scenarios. A comprehensive understanding of each process includes recognizing different variations and configurations. For instance, a single process might have multiple workflows depending on specific conditions or departmental needs. Identifying these variations is crucial for planning accurate and effective automation strategies. You can internally audit your business processes or work with a partner (like ICG) who can perform a Business Systems Review across departments. Once you have a complete inventory of the processes and their variants within your VISUAL ERP system, you can develop a tailored automation plan. This plan should strategically align with your organization’s goals and operational requirements, ensuring that automation enhances efficiency and consistency across all processes. By thoroughly understanding and documenting these processes, you set the stage for a successful automation journey that delivers real value to your organization. |

|

|

Evaluating Processes for ERP, Data Collection, and Automation: Identifying High-Value OpportunitiesIf you’re planning to buy a new ERP system for your company, be prepared to go through the process of adjusting your current business processes to the new system during implementation. Considering the large number of ERP implementations providers execute, they have developed many best practices to make the most of your investment. Take advantage of the built-in knowledge of your system and fight against the temptation to go back to the old way. Note, that only some processes are suited for automation; understanding which ones to prioritize is key to a successful automation strategy. Typically, the best candidates for ERP automation are high-volume processes or workflows that involve repetitive tasks. These processes often present the most significant opportunities for efficiency gains. For instance, automating data entry tasks that involve manually transferring information between systems can greatly enhance employee satisfaction and productivity. To effectively prioritize automation opportunities, conducting a thorough automation assessment is crucial. This evaluation will help you identify which processes offer the highest value and potential ROI for your enterprise automation initiative. By carefully assessing and prioritizing processes based on their impact and potential benefits, you can ensure that your automation efforts align with both operational goals and customer experience enhancements. |

|

|

Prioritizing Implementation/Reimplementation: From the Top DownFocusing on implementation or a reimplementation can be difficult. It starts at the top, and the executive leadership team must be on board. From the CFO and CEO to support staff, an ERP implementation affects everyone in a company. For a successful implementation, it is essential to get support from all parties. Some organizations make decisions at C-Suite levels, while others have a broader spread of management. To succeed in this first point, which is to get the buy-in of the leadership team, you need help from people at all levels, and it must be obvious that everyone is on board in a leadership capacity. |

|

|

Leveraging ERP Automation During Implementation: Enhancing Workforce StrategyImplementing automation can significantly free up your team's time by handling routine and repetitive tasks. As a result, employees who were previously occupied with these tasks can be redirected to focus on more strategic and value-added activities. Furthermore, power users can be trained to oversee and maintain the automation systems, ensuring that they continue to operate efficiently and adapt to any changes in the business environment. However, the introduction of automation necessitates a realignment of your workforce strategy to reflect the evolving needs of your organization. It's important to assess how automation impacts your workforce and adjust your talent management approach accordingly. With employees now available for more critical roles, there is an opportunity to re-skill or up-skill them to address other areas of need within your organization. |

|

|

Staying ALL IN: Keeping All Information "IN" the ERP After ImplementationIt’s essential to stick with the system and established processes after everything is in place. Make sure people don’t revert to old habits and that they adapt their behaviors to the new system. Maintaining momentum is crucial to successfully adopting any new system or idea. It would be best to reduce manual processes and ensure teams don’t revert to spreadsheets. If you’re not carefully managing the day-to-day adoption, there is a risk that people will fall back to old ways in the subsequent months. Implementing or reimplementing an ERP system is vital to ensure that you get all the benefits from your investment and that employees are continually informed about any changes. This is a great time to reinforce best practices. Recognize people in your organization who embrace the new processes and celebrate team and individual successes. Build up a company culture of adoption and being able to use the new system, and you will go far! |

Leveraging the 30+ years of ERP implementation experience of ICG and our proficiency with VISUAL ERP can be a game-changer for your business. ICG’s deep understanding of VISUAL ERP's capabilities, combined with our experience in deploying ERP shop floor and workflow solutions like MFGStream, positions us as a valuable partner in optimizing your ERP strategy. ICG's expertise ensures that you can overcome common hurdles, streamline your automation initiatives, and achieve the strategic outcomes you aim for.

By partnering with ICG, you gain access to seasoned professionals who can tailor VISUAL ERP’s automation solutions to fit your unique business needs. Our guidance will help you navigate the complexities of automation, ensuring a smoother implementation process and delivering tangible improvements in efficiency and productivity.

Learn more about automation and other relevant topics

at ERP Tech Summit 2024 coming up September 17-19!

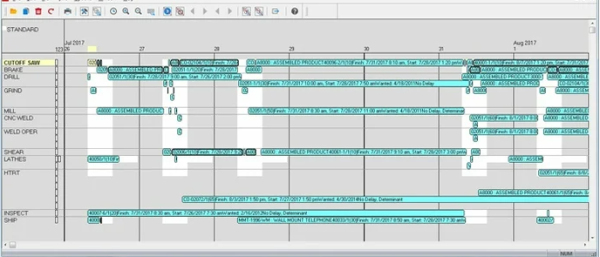

VISUAL ERP Quick Tip: The Scheduling Window in VISUAL is an underutilized resource! This graphical display of work scheduling across operations generates run sheets for each department, syncing your entire manufacturing operation. The system understands when each step of every work order is scheduled to run, when each material is needed, what it is needed for, and predicts when each work order will be completed.