|

Have you experienced stock replenishment issues because of inefficient workflows? You're not alone. Effective stock replenishment is the basis of operational excellence for manufacturers. When a leading manufacturer encountered inventory challenges within their Fourth Shift ERP system, they turned to ICG’s seasoned experts who have over 30 years of proficiency in Fourth Shift ERP solutions. This partnership ignited a journey towards optimization, streamlining, and ultimately, improved ROI. Understanding the manufacturer's unique environment and specific needs was vital for ICG. Armed with insights gained from comprehensive conversations and assessments, we devised a solution to improve the stock replenishment process. Here’s how it happened: |

|

1. Identified Pain PointsICG delved deep into the manufacturer’s operational framework to pinpoint bottlenecks and inefficiencies affecting the stock replenishment process. Through meticulous analysis, they uncovered the root causes of delays and discrepancies, laying the groundwork for targeted interventions. |

|

2. Tailored SolutionWith a strong understanding of the manufacturer’s pain points and requirements, ICG crafted a detailed solution to tackle their challenges utilizing MFGStream, a fully integrated, powerful ERP-agnostic platform that allows complete customization and automation of your manufacturing or distribution facility. Central to this strategy was the integration of work centers as trigger points for stock replenishment, leveraging MFGStream's scanning technology to initiate and track requests seamlessly. |

|

3. Queue Management SystemICG implemented a robust queue management system within Fourth Shift ERP, revolutionizing stock request processing. Each request generated a comprehensive record encompassing crucial details such as the requesting date/time, request ID, work center, and stock specifications, ensuring transparency and accountability at every stage. |

|

4. Streamlined WorkflowThe heart of the solution lay in the deployment of two scan transactions within MFGStream: collect and deliver. The collect transaction empowered workers to swiftly retrieve the needed items, transporting them to a temporary delivery location with precision and efficiency. Then, the deliver transaction facilitated the transfer of requested items from the temporary location to the designated work center and removed the request from the queue. This streamlined workflow minimized manual errors, accelerated response times, and optimized resource utilization. |

|

5. Performance Monitoring and OptimizationBeyond implementation, ICG remained committed to the manufacturer’s long-term success by instituting robust monitoring mechanisms. Real-time tracking of elapsed time between request and delivery data collected by MFGStream and analyzed through business intelligence software (like Tableau or Power BI) enabled continuous performance evaluation, paving the way for iterative refinements to further enhance efficiency and agility. |

After updating their Fourth Shift ERP and implementing ICG’s innovative solutions through the MFGStream platform, the manufacturer saw measurable improvements to their stock replenishment operations. Delays were minimized, productivity soared, and operational costs dwindled, creating a ripple effect of enhanced competitiveness and customer satisfaction.

The success story of this manufacturer underscores the profound impact of strategic partnerships and tailored solutions in navigating the complexities of modern manufacturing. With the right expertise and innovative approach, even the most daunting challenges can be transformed into opportunities for growth and advancement.

Learn more about MFGStream and other relevant topics

at ERP Tech Summit 2024 coming this fall!

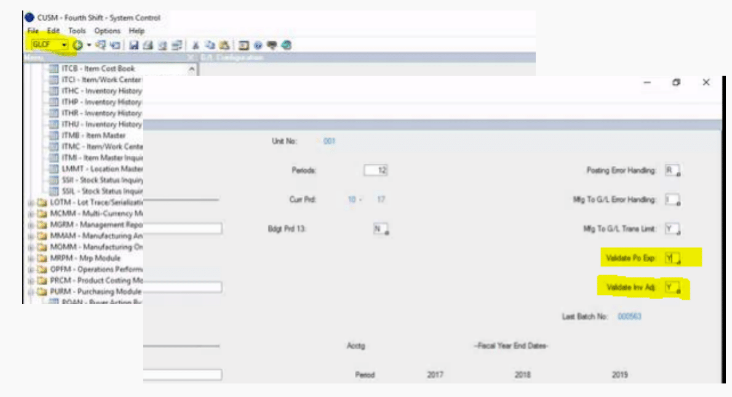

Fourth Shift ERP Quick Tip: In the GLCF/GLCA Settings, you can now determine whether an account number can be used for INVA’s or for G-type Po’s. If either GLCF option is Set to Y, then only accounts with a similar setting on GCLA Account Attributes will be valid for the transactions.